Managing caries and motivating change, part 2: Motivational interviewing

How do you motivate your patients? Discover how caries risk assessments and motivational interviewing tactics can help you connect with…

When choosing an attachment material for use with clear tray aligners (CTAs), doctors are faced with the choice between a flowable or paste composite.

Flowable composites offer easy dispensing and quick tray filling, but they are believed to suffer from lessened wear resistance, worse staining, lower bond strength and the presence of bubbles created during dispensing. Pastes, on the other hand, can take longer to apply and pack, but they are believed to have more robust physical properties and can be used to fill trays ahead of time without fear of the material flowing out of place.

Deciding between a paste or a flowable can feel like losing out on some aspects of critical performance, but many assumptions about the differences between pastes and flowables do not hold true when examining the new Clarity Attachment Material. Solventum scientists have leveraged decades of experience in composites to develop a flowable attachment material with enhanced physical properties, providing the best of both worlds. It offers a flowable’s ease of application without sacrificing bond strength, wear resistance or stain resistance. It can be pre-filled just like a paste, and it even comes with a new bubble-free syringe for added ease of use.

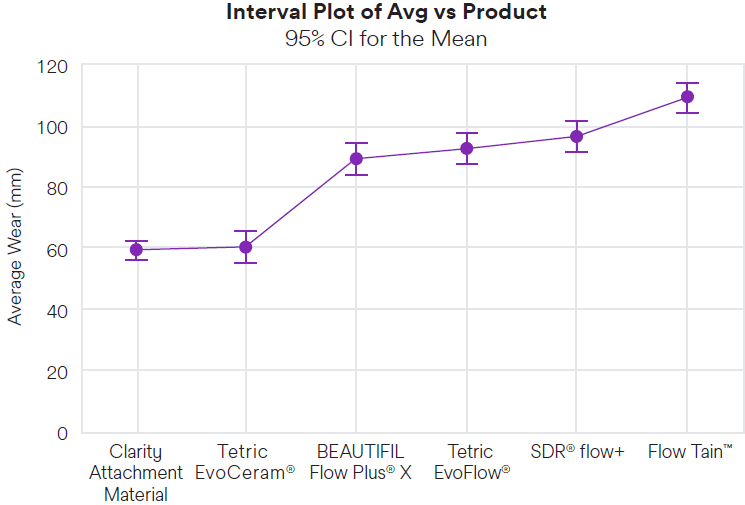

Figure 1. Wear rate data created from a 3-body wear test (antagonist wheel, sample wheel and a mildly abrasive millet slurry). Measurements with a profilometer were taken to examine total change in surface wear over the course of the test. ANOVA based analysis shows the Clarity Attachment Material performs equivalently to the leading paste material.

The shape integrity of each attachment is critical to the movement of teeth during clear tray aligner therapy because even subtle changes in the attachment shape can affect the direction and magnitude of applied forces. Once cured, the material’s wear resistance is a key property for maintaining the attachment’s shape. Because of their higher filler content, pastes often display superior wear resistance when compared to flowable composites, but it is important to remember that filler content is not the only variable. During 3-body wear testing the Clarity Attachment Material demonstrated equivalent durability to Tetric EvoCeram® (a leading paste) and better durability than other leading flowables. Figure 1 shows the paste-like ability of the Clarity Attachment Material to resist wear, allowing for a crisp and accurate attachment shape over the course of treatment.

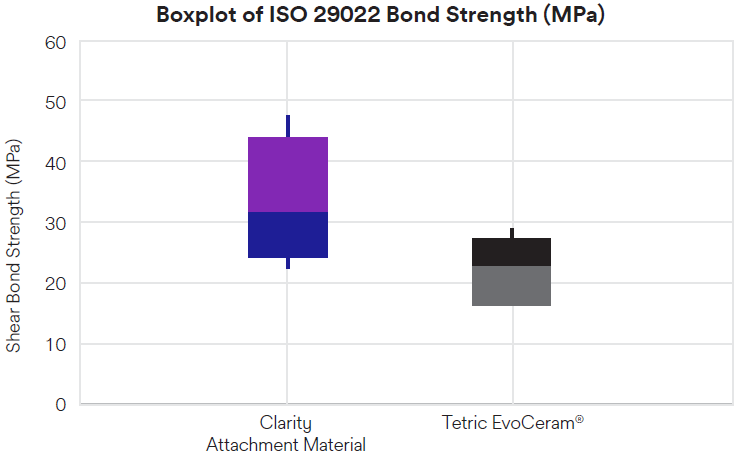

Another critical feature for treatment is the bond strength of the attachment to the tooth surface. In traditional bracket-based orthodontics, the adhesive must lock into the mesh base of the bracket, provide sufficient cushion to fill the gaps below the bracket surface and stay in place before curing. These requirements have resulted in a generalization that pastes tend to have higher bond strength when compared to flowables. However, this generalization does not translate to the creation of attachments. Critically, there is no bracket-toadhesive interface when creating an attachment, and so the primer-to-adhesive interface becomes the focus of bond strength when considering an attachment material. Here we find that the Clarity Attachment Material has equivalent bond strength to paste adhesives, meaning you are not sacrificing any bond strength for the convenience of using a flowable. A further general takeaway is that the bond strength of an attachment is not very dependent on the attachment material at all. Shear bond strength

testing according to ISO 29022 revealed that the failure overwhelmingly occurs at the tooth-primer interface.

Figure 2. Samples are tested for shear bond strength according to ISO 29022 using the ground enamel surface of bovine teeth. All samples failed at the tooth-primer interface, supporting the conclusion that flowables and pastes have equivalent performance when used as an attachment material.

Another concern for flowables is that pre-filling trays is not advisable. The primary reason is that traditional flowables will flow under the force of gravity, making prefilling near impossible. The second potential reason is that leaving the attachment material in the tray exposed to air for too long may result in a poor curing performance later as the photocuring agents begin to evaporate off.

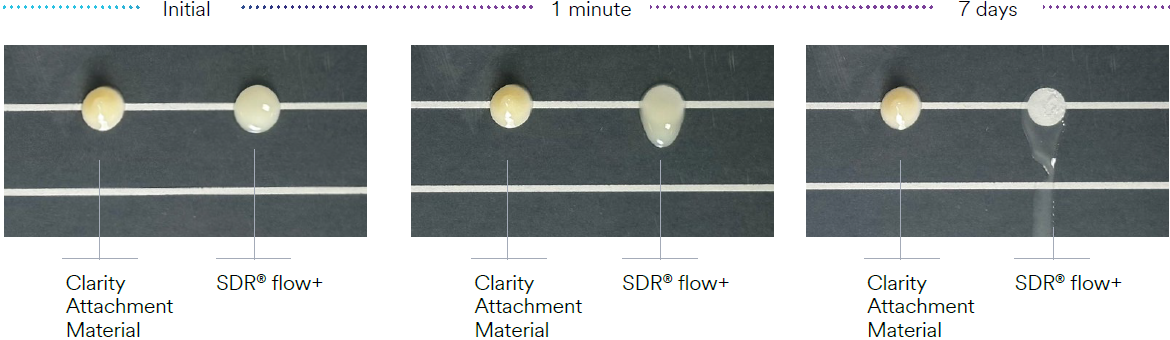

A worst-case scenario for the first problem is clearly a vertical surface where gravity can have its fullest effect. Figure 3 illustrates the result of leaving Clarity Attachment Material on a vertical surface for 7 days. It behaves exactly like a paste, showing no observable movement. In contrast, a traditional flowable material moves noticeably within minutes.

Figure 3. Unlike more traditional flowables, the Clarity Attachment Material does not flow when left on a vertical surface for up to a week.

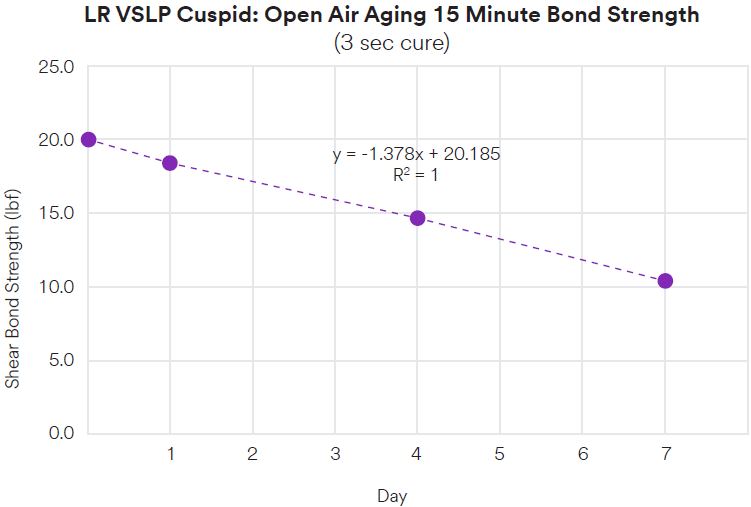

The second potential problem is addressed with data from another stress test of the material’s performance. We use the worst possible bonding situation for a flowable: a curved metal bracket bonding surface, low cure time, open-air aging and a debonding test only 15 minutes after curing. This creates a much worse situation than ISO 29022 for the material’s performance, and so it functions as a lower bound on the material’s performance. Another reason we use this test as a measure is because, as we saw in the ISO 29022 test method, the primary bond being tested was actually the bond of the toothprimer interface. It is easier to observe the loss of performance in the flowable itself when it must bond to a more difficult surface such as the bracket base. Using this method, we see that the material’s bond strength decreases linearly with time, leading to a 25% drop from its initial bond strength after 4 days of being exposed to the open air. This puts it just on the edge of acceptability in this test environment, and therefore we can have confidence that its performance as an attachment material is sufficient out to 4 days of exposure to air.

Figure 4. Shear bond strength of lower right 3M™ Victory Series™ Low Profile cuspid brackets bonded to bovine teeth with Clarity Attachment Material. The cure time was 3 seconds mesial/distal. Each bracket was debonded 15 minutes after cure. N = 15 at each time point.

Handling preferences are subjective, yet there are still aspects of a flowable’s handling that can make it difficult to successfully fill and bond a tray full of attachments. As shown in Figure 3, the flowability of the composite can be too high to successfully stay in the tray when bonding. The logical solution is to increase the viscosity of the flowable when at rest, but this can also be taken too far, leading to a situation where the flowable material maintains small shape irregularities after dispensing. Figure 5 helps to illustrate this point. The Clarity Attachment Material stays where it is placed, but it also adapts to small irregularities created during dispensing. This leads to a smooth and even surface for bonding attachments.

This feature is also a result of a carefully tuned underlying material property called structural regeneration time. This may sound complex, but it is essentially a measure of how quickly the material returns to its at-rest state. Tuning this underlying property allows the Clarity Attachment Material to have the self-leveling behavior of a flowable while being dispensed and applied to the tray, but to then become more paste-like a few seconds after application. If structural regeneration time were too long it may result in a flowable that slips from the tray long before it stiffens up, or if it were too short the flowable would too quickly become stiff and not settle out smoothly after dispensing.

Figure 5. Clarity Attachment Material (right) compared to Dentsply Sirona’s SDR® flow+ (middle) and GC Aligner Connect™ (left). This image was taken 1 minute after dispensing. It shows how the Clarity Attachment Material delivers a good rheological profile that smooths out small imperfections, but does not flow enough to flow out of the tray (further evidence of this claim in Figure 3).

Aligner therapy is an aesthetics-forward treatment option, so staining is naturally a concern. The attachment material’s performance against liquid staining agents such as coffee and red wine is especially important to test because patients may attempt to drink without removing their aligners. This leads to a situation where the attachment material is exposed to the staining agent longer than would be expected as it sits in the tray material, especially if patient compliance is low.

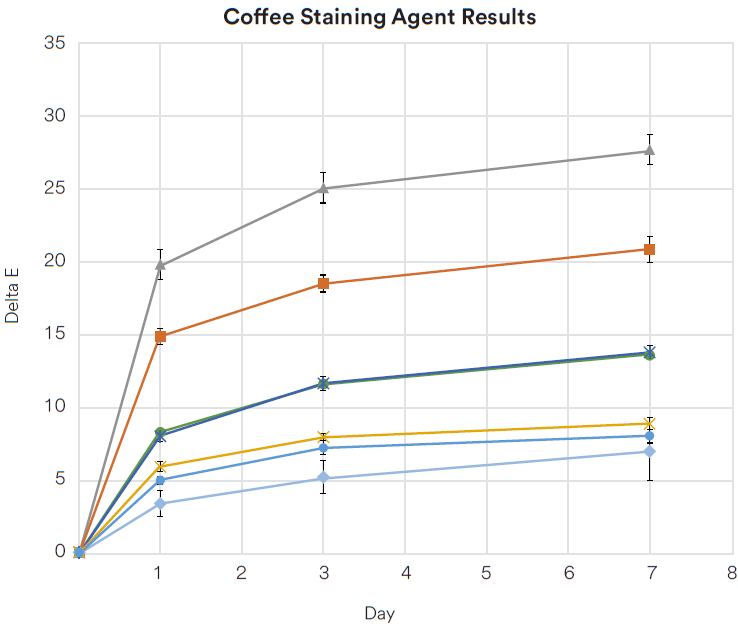

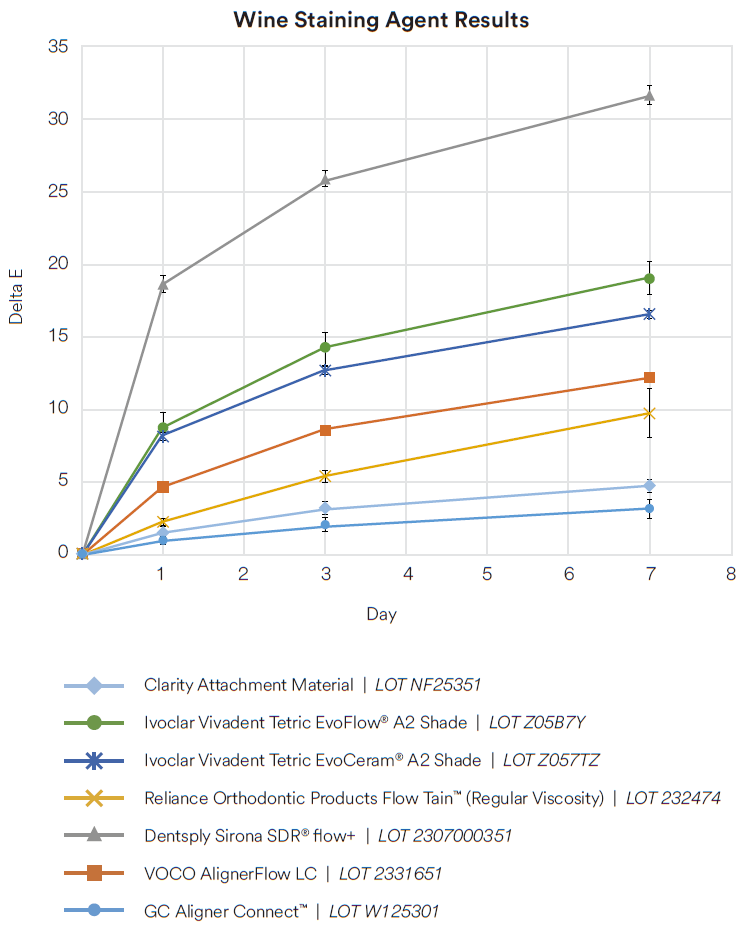

Higher stain resistance is commonly attributed to pastes over flowables by pointing to the larger percentage of filler material in a paste. This point is true as far as it goes, but every composite needs a resin component, and stain resistance can vary significantly based on how well the resin component is designed to resist staining. Even though a paste may have less resin as a percentage of its total formulation, it remains the weak point for staining. This means a flowable material like Clarity Attachment Material can perform extremely well against common staining agents because its resin matrix is more resistant to staining. A glance at the data in Figures 6 and 7 shows the difference in performance is significant: not only does the Clarity Attachment Material perform better than other flowables, it also outperforms the well-known paste material Tetric EvoCeram®.

Figures 6 & 7. Cured disks of 15mm diameter and 1mm thickness were submerged in staining agents after taking an initial color measurement using an X-Rite Spectrophotometer Color measurements were then taken at 1, 3, and 7 days using the same spectrophotometer. Each sample was tracked individually. N = 3 for each time point, material, and staining agent. Standard deviation is displayed on graph.

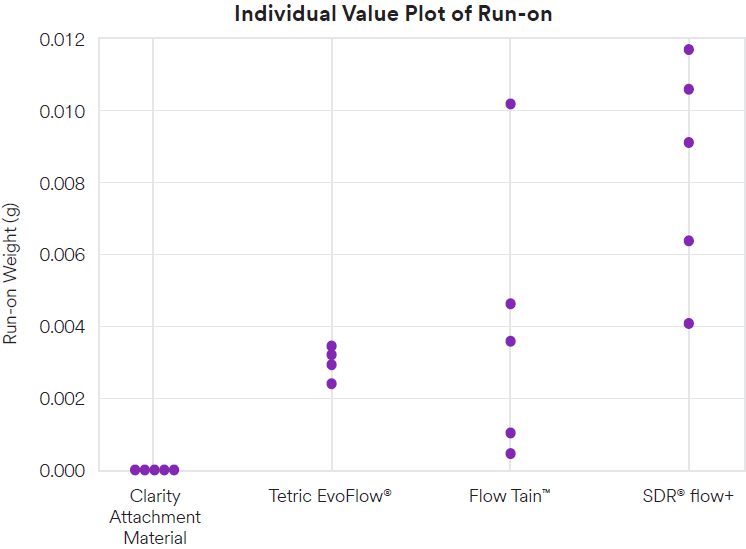

Figure 8. Each data point is a newly opened syringe with its supplied dispensing tip. A total of 0.2g of material was dispensed, the tip was wiped clean using Kimwipes™ Delicate Task Wipes, and the syringe was then left on a flat surface over wax weigh paper for 2 minutes. After 2 minutes the material that continued to ooze out of the syringe was weighed. The Clarity Attachment Material consistently does not ooze after dispensing.

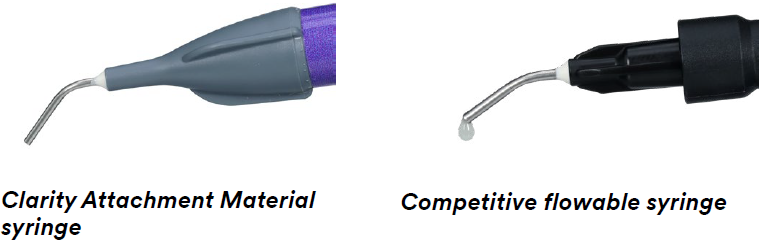

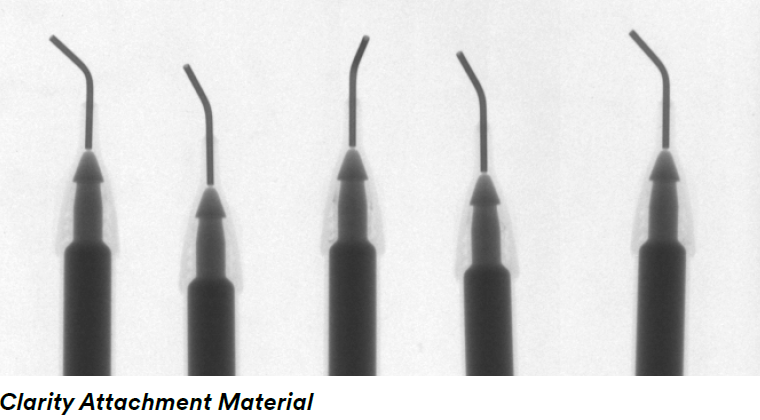

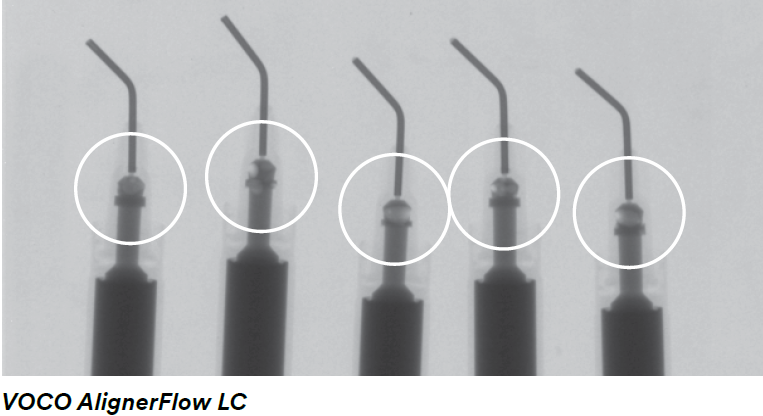

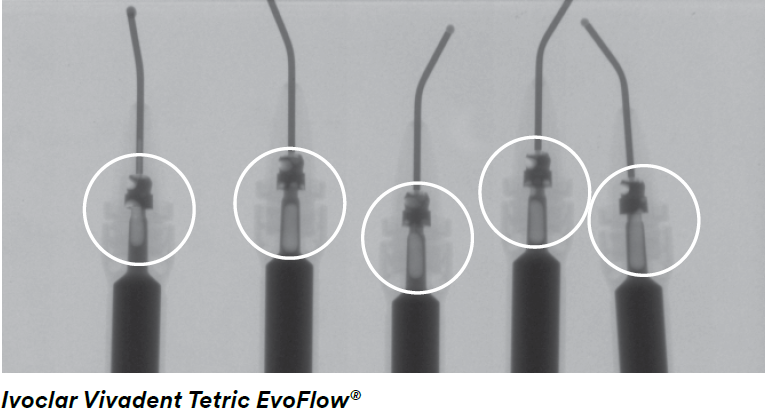

The final major pain point of flowables is the presence of bubbles. Nothing ruins a flowable composite’s ease of application faster than a bubble. For this reason, Solventum scientists have leveraged their bubble-free syringe technology to give you a bubble-free starting point when dispensing. A glance at the X-ray images of the newly opened syringes in Figure 10 shows the obvious presence of air bubbles in many competitor syringes.

The delivery system also offers a mess-free application process, eliminating the annoyance of cleaning up run-on material that may ooze out of the syringe after dispensing is finished. With the Clarity Attachment Material syringe, there is no run-on after dispensing. Compare this to other common flowables, which continue to ooze material after dispensing as seen in Figure 9.

Figure 9. Other common flowables may continue to ooze material after dispensing.

Figure 9. Other common flowables may continue to ooze material after dispensing.

Figure 10. X-ray images of newly opened syringes show the obvious presence of air bubbles in many competitor syringes.

Most clinicians agree, aligner therapy can only be effectively delivered with high quality attachments. Defects, debonds and other challenges can derail best-laid plans. With the launch of Clarity Attachment Material, scientists at Solventum have leveraged our 75-year legacy of material science, innovation and process technologies to empower clinicians with durable, highquality materials. Applying the success of our proprietary syringe design in other dental consumables, we are making it easier to reliably create bubble-free, esthetic attachments.

3M Health Care is now Solventum, yet we remain committed to solving what matters most: enabling better, smarter and safer healthcare for you.

We would love to know how we can improve the blog for you. Please answer our survey below. It only takes a few minutes.

You can answer anonymously if you prefer.

Authored by:

Product Development Specialist

Jake Johnson received B.S. Degrees in Chemical Engineering and Chemistry from University of Minnesota, Twin Cities in 2012. He joined 3M in 2013 as an adhesive product developer in the consumer electronics industry before eventually transitioning to orthodontic bonding materials with what is now Solventum.

Sr. Product Development Engineer

Mitchell Hirsch received his Bachelor of Materials Science and Engineering from University of Minnesota, Twin Cities in 2016. That same year he joined 3M’s Oral Care Solutions Division to work on clear tray aligner films, adhesive precoat technology and metal brackets.

How do you motivate your patients? Discover how caries risk assessments and motivational interviewing tactics can help you connect with…

Caries is a complicated multifactorial disease. In this two-part series, explore how caries risk assessments can help improve evaluation and…

Zirconia may be part of your everyday vocabulary, but how much do you know about this ceramic material? Learn more…