Zirconia puzzle: what makes zirconia unique and how to choose the right zirconia

Zirconia may be part of your everyday vocabulary, but how much do you know about this ceramic material? Learn more…

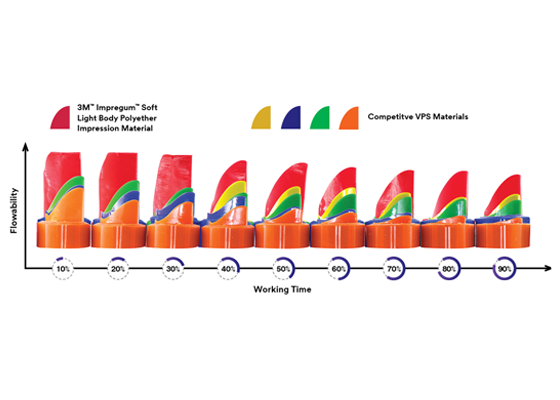

3M put the flowability of top impression materials to the test with the “shark fin challenge.” See how some materials reproduce fine details consistently over the entire working time – and how some fall short.

In dental restorative work, first impressions matter most: the final fit of a restoration depends on the accuracy of the impression, which is in turn affected by the capabilities of the impressioning material. A clinician’s choice of impression material often comes down to personal preference, or simply what they first learned to use in dental school. But it’s important to know how your choice can affect the accuracy of the impression and the implications for a key property – flowability.

Good flow assures that your impressioning material will reach and fill all the nooks and crannies of your patient’s teeth, giving you enough information for an accurate reproduction. But with some impression materials, flowability decreases over the working time – which means you could be losing fine details. And an ill-defined impression can result in ill-fitting restorations, lengthy crown adjustments and costly, time-consuming remakes.

Let’s take a closer look at flowability and what it could mean for your procedure.

It all comes down to chemistry. Vinyl polysiloxane (VPS) and polyether materials behave differently with regards to flowability because of their distinct chemistries and setting reactions. Some VPS materials, for example, start setting as soon as they are mixed – while others only begin to set at the end of their working time. Polyether, on the other hand, is more predictable: it remains flowable throughout placement and then “snap-sets” at the end of its working time. Because polyether-based materials remain flowable longer, they give clinicians more working time for large or challenging cases and implants.

The intra-oral situation itself can also affect your material options. Polyether is well suited for challenging scenario, such as:

Deep sulcus or moisture: In cases where you need to reach vital areas, polyether delivers high flow without high pressure1

Moisture: When there’s a significant amount of moisture that isn’t easily controlled during the impression process – such as bleeding, tissue exudation, salivation, and subgingival margins.

Extended restorations with multiple preparations: If extended working time is required, such as for cases with more than 3 preparations (e.g. bridges, implants, combined removable prosthesis)

When evaluating the flowability of your impression material, ask yourself these key questions:

An impression material should remain flowable throughout the entire working time. If it begins to set during this critical time, you could end up with an inaccurate impression – jeopardizing the results of the entire procedure. Large cases and long working times aren’t the only considerations, either: consistent flow behavior is even more important in fast-setting materials, where every second of the working time counts.

So how can you get a clear picture of your material’s flow capabilities? Rheometric techniques can be used to assess basic rheological parameters of elastomers, such as viscosity, rigidity, and elasticity, and their changes during setting. But a different kind of test is needed to truly see how a material behaves under controlled pressure over the course of its working time.

That’s why 3M developed the “shark fin test” to simulate the flow of impression material into the sulcus. Here’s how it works: First, a receptacle is filled with impression material. Then a V-shaped weighted mold sinks into it. The displaced material flows up into the mold, forming a shark fin shape. The greater the material’s flowability, the taller the fin.

Watch the test in action here:

By repeating the test at specific points during a material’s working time, you can see how flowability declines throughout the working time – or not.

In this “school of sharks,” you can clearly see one set of fins rising above the rest, revealing consistent flow at every point measured over its working time. The Shark Fin Test indicated that 3M™ Impregum™ Super Quick Polyether Impression Material shows constant viscosity throughout its entire working time. It continued to capture void-free detail, while the tested VPS materials couldn’t even rise halfway up the shark fin mold. At each measurement point throughout the working time, Impregum Super Quick Impression Material showed significantly better – and more consistent – flow than the VPS materials tested.

This sustained flowability throughout the working time is typical of all 3M™ Impregum™ Polyether Impression Materials. The snap-set behavior of polyethers means a brief transition between working and setting time, rather than the gradual decline in flow throughout working time, as happens with VPS materials.

When an impression material’s flowability decreases over the working time, it can result in distortions, displaced wash material and an ill-fitting restoration. Sustained flowability, on the other hand, allows the full indicated working time to be used. Polyether materials have a distinct clinical advantage when it comes to flow: even at the end of the working time, they flow easily around the preparation, thereby capturing more detail. This helps avoid problems associated with premature setting – and helps ensure a proper fit for your restoration, right from the start.

Are you experiencing loss of detail in your impressions? Download our troubleshooting guide.

Margeas, Robert C. “New Polyether Dispensing Method, Same Polyether Accuracy.” Inside Dentistry, 2009, www.aegisdentalnetwork.com/id/2009/08/new-polyether-dispensing-method-same-polyether-accuracy.

Zirconia may be part of your everyday vocabulary, but how much do you know about this ceramic material? Learn more…

Achieving the correct shape is vital to a natural-looking anterior composite restoration. Learn how the 3M™ Filtek™ Matrix, paired with…

Direct composite restorative procedures can be challenging, particularly when it comes to esthetic cases. Discover how new techniques and tools…