Zirconia puzzle: what makes zirconia unique and how to choose the right zirconia

Zirconia may be part of your everyday vocabulary, but how much do you know about this ceramic material? Learn more…

For over 60 years, 3M material scientists have been at the forefront in working with multi-layer films in an array of industries, from industrial to commercial to health care.

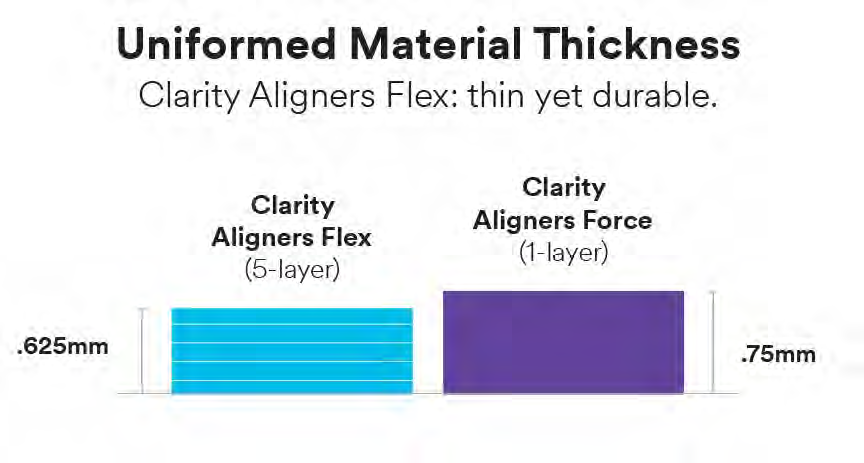

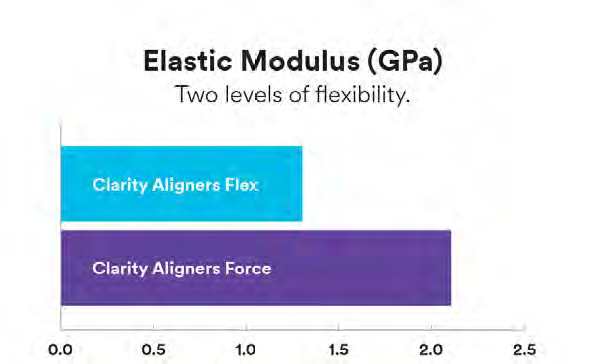

Drawing from this expertise, we saw an opportunity to improve the appliance capability of clear aligners through the development of new film constructions. Instead of offering an aligner system made from one material that applies force through different thicknesses, the 3M™ Clarity™ Aligner Flex + Force system was created, using advanced copolymer materials to achieve multiple objectives.

Since the introduction of this treatment option in the late 90s, doctors have adapted treatment protocols to address the force or flexibility limitations that have traditionally been part of using aligners. As we talked with orthodontists and learned more about which aligner properties are most desirable, we concluded that no single material had all the necessary characteristics. That’s when we got to work on expanding our aligner system to include a new, more flexible multi-layer option.

Since 3M first developed overhead projector film 60 years ago, we have further established a world-class, multi-layer optical film platform with precision engineering and strict control of multiple material and process variables. Using our expertise in polymers and multi-layer film technology, we set out to create the next generation multi-layer material for the aligner tray application. The result was 3M™ Clarity™ Aligners Flex.

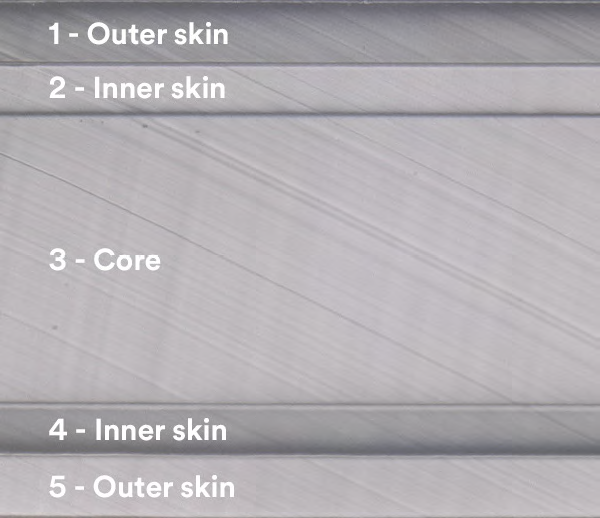

The first step was determining the ideal performance requirements for selecting the material properties we wanted each layer to have. We knew the outer layer needed to resist staining, scratching and discoloration. The inner layers needed to provide mechanical durability such as cracking and tearing resistance, force persistence, flexibility and ultimately, resilience.

Proprietary blend of materials deliver a synergistic effect greater than any single material we could develop.

Clarity Aligners Flex and 3M™ Clarity™ Aligners Force (the new name for our original material) form a system with different properties to address a range of needs for orthodontists. While developing the Clarity Aligners Flex part of the system, we received input from orthodontists to address these issues:

From a materials standpoint, the properties needed to address these issues are somewhat at odds. For example, it’s challenging to combine the flexibility needed for easy insertion and removal with the durability needed for force persistence and cracking resistance. Meeting these disparate requirements collectively is not straightforward, but we were up for the challenge.

Working with an existing technology doesn’t mean there are no challenges when applied in a new way. For one thing, we had come up with a way to combine materials that had very different properties and discovered that we had to break all the rules set for multilayer coextrusion. We called on our multi-layer optical film technology group, and they designed a new manufacturing process for combining these supposedly un-combinable materials. There are not many companies that know polymer science well enough to be able to adapt in this way and develop the five-layer film solution used in Clarity Aligners Flex.

Creating a new aligner from scratch didn’t involve a single “eureka” moment. It was an iterative process of design and discovery. First, we had to determine which materials would be part of our multi-layer solution. We settled on a family of copolyesters as the materials that were best suited to the challenges presented. We then developed the layers with varying levels of stiffness and flexibility. Each layer has its own thickness and properties that when combined, creates a synergistic affect that is greater than any single material we could achieve. The materials, the shape of the aligner and how it’s formed during manufacturing all contribute to the overall performance of Clarity Aligners Flex.

At its core, orthodontics is all about coaxing the body to remodel itself. Aligners are good at gently suggesting that to the body. But to achieve tooth movement, aligners also need to maintain force over the course of weeks. The material in Clarity Aligner Flex has excellent force persistence. In fact, Clarity Flex Aligners maintain a consistent force over two weeks, retaining 75% of its initial force, toward a goal of prediction accuracy in treatment designs.

3M™ Clarity™ Aligners Flex + Force have two levels of flexibility.

Clarity Aligners Flex are easy for patients to insert and remove. This may help with treatment compliance. They are also stainresistant and highly durable, withstanding hundreds of insertion and removal cycles in the laboratory. Durability is also evident in providing tear resistance and resilience when using hook cut-outs and bite ramps.

Clarity Aligners Flex can cover the gingival margin, giving orthodontists more choices for placement of attachments—which also engage well with the new material.

The final result achieved our goals of advancing the materials science in aligner treatment. The new Flex material strikes the balance of the flexibility needed for easy insertion and removal with the rigidity needed for force persistence, durability, and stain resistance.

3M is uniquely positioned to advance the practice of orthodontics. We can spot opportunities and uncover solutions with extremely deep and varied expertise in materials science. Paired with our history in oral care and our mastery of polymers, we look forward to a future of continued innovation for orthodontists and the patients they serve.

We would love to know how we can improve the blog for you. Please answer our survey below. It only takes a few minutes.

You can answer anonymously if you prefer.

This article was written by Karl Geisler, Tahua Yu, and Jerry Hall.

Zirconia may be part of your everyday vocabulary, but how much do you know about this ceramic material? Learn more…

Achieving the correct shape is vital to a natural-looking anterior composite restoration. Learn how the 3M™ Filtek™ Matrix, paired with…

Direct composite restorative procedures can be challenging, particularly when it comes to esthetic cases. Discover how new techniques and tools…